Nominal voltage: 3.7V

Nominal capacity: 800mAh

Diameter: 14mm

Height: 50mm

Application: instrumentation, consumer electronics

Nominal voltage: 3.6V

Nominal capacity: 800-1500mAh

Diameter: 18±0.2mm

Height: 50±0.3mm

Application: security communication, rail transit

Nominal voltage: 3.7V

Nominal capacity: 2000-3500mAh

Diameter: 18±0.2mm

Height: 65±2.0mm

Application: special equipment, medical equipment, robot, etc.

Nominal voltage: 3.6V

Nominal capacity: 3000-4800mAh

Diameter: 21mm

Height: 70mm

Application: digital devices, power tools

Nominal voltage: 3.2V

Nominal capacity: 3200~3500mAh

Diameter: 26.2mm

Height: 65.6mm

Application: power/energy storage, robot, emergency backup

Nominal voltage: 3.2V

Nominal capacity: 4500-6500mAh

Diameter: 32.4±0.3mm

Height: 70.5±0.2mm

Application: instrumentation, backup power source, special equipment

Cylindrical lithium-ion battery is a lithium ion battery with cylindrical shape, so called cylindrical lithium-ion battery. According to the anode materials, cylindrical li-ion battery are divided into lithium cobalt oxides (LiCoO2), lithium manganese (LiMn2O4), lithium nickel manganese cobalt (LiNiMnCoO2 or NMC), lithium aluminum nickel cobalt (LiNiCoAlO2 or NCA), lithium iron phosphate (LiFePO4) and lithium titanate (Li4Ti5O12).

There are many types of cylindrical lithium batteries, including 14500, 14650, 18500, 18650, 21700, 26650, 32650, etc. They are widely used in special equipment, medical equipment, instrumentation, handheld equipment, security and communication.

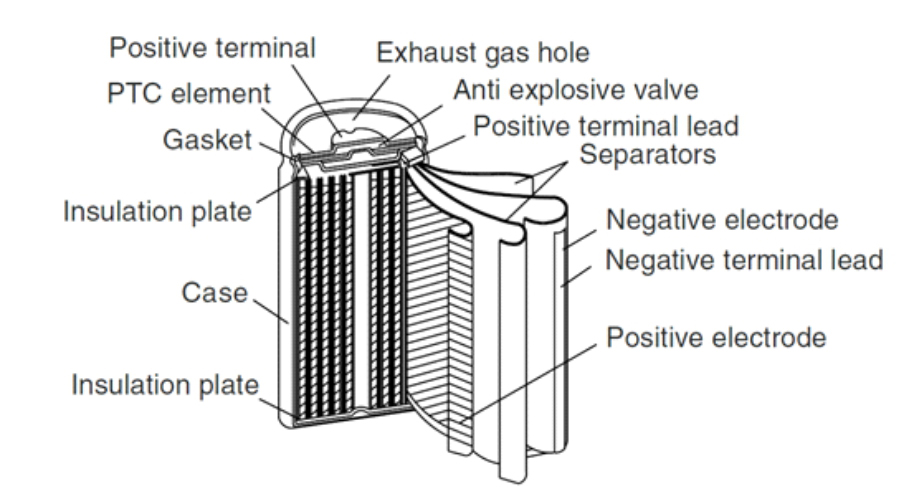

A typical cylindrical battery structure includes: case, cap, positive electrode, negative electrode, separator, electrolyte, PTC element, gasket, anti explosive valve, etc. Generally, the battery case is the negative electrode of the battery, and the cap is the positive electrode of the battery. The battery case is made of nickel steel plate.

Compared with lithium pouch cell and prismatic lithium battery, cylindrical lithium battery has the longest development time, high degree of standardization, mature technology, high yield and low cost.

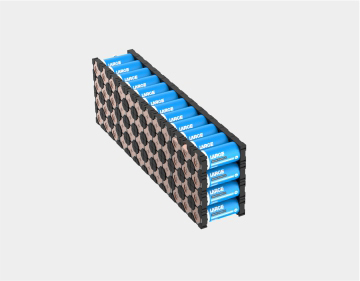

In a lithium ion battery pack, for the sake of safety and effective management of hundreds of single battery cells, the cells are not randomly placed in the case of the lithium ion battery, but are arranged in an orderly manner according to modules and packages. The smallest unit is battery cell, many of which can make a module, and several modules can make a battery pack.

Battery cell is the smallest unit of the lithium ion battery pack, and it is also the energy storage unit. It must have a high energy density to store as much power as possible, so that the device can work for a long time. In addition, the life of the lithium ion battery cell is also the most critical factor. The damage of any one battery cell will affect the entire battery pack.

Constitute multiple battery cells enclosed by the same battery case make a module. It connects to the outside by a uniform interface.

When several modules are jointly controlled or managed by BMS and thermal management system, it is called lithium battery pack.

18650-13S8P Low Temperature Charge/discharge LiFePO4 Battery Nominal voltage:32V Nominal capacity:20Ah 305*155*115mm(Max)

26650-4S10P Medical Ultrasonic Machine Lithium Ion Battery Pack Nominal voltage: 12.8V Nominal capacity: 33000mAh Battery dimension: 345×160×75(Max)

32650 24V 100Ah LiFePO4 Battery Pack Special Emission Equipment Battery Cell: 32650/3.2V/6Ah Dimension: 350*320*180mm Application: ocean monitoring, industrial equipment, emergency power supply, etc.

In order to ensure the safety of cylindrical lithium battery, domestic and foreign organizations have formulated various corresponding safety testing standards for cylindrical lithium ion battery. The general testing standards generally divide the safety testing items into the following four categories:

Place a fully charged cylindrical lithium ion battery cell on a plane. Use a steel needle with a diameter of 2.5~5mm to puncture the battery cell and maintain it for 10min. If the battery cell does not fire or explode, it passes the test.

Place the fully charged cylindrical lithium ion battery cell on the impact platform, and drop the 10kg hammer freely at a height of 610mm±25mm to impact the battery cell fixed on the fixture. If the battery cell does not fire or explode, it passes the test.

Place a fully charged cylindrical lithium ion battery cell on a plane. Use oil cylinder to apply 13± 0.78KN extrusion pressure. Then the battery has plane extrusion by the steel bar with 32mm diameter. If the extrusion pressure reaches the maximum value, and the battery cell does not catch fire or explode, the battery cell passes the test.

Discharge the cylindrical lithium battery cell at a constant current to the discharge cut-off voltage according to the standard discharge current, and then put the battery cell in the explosion-proof box. The battery anode is connected to the DC cathode, and the battery cathode is connected to the DC anode.

The cylindrical lithium battery cell is fully charged with 1C and overcharged with 10V 3C. When the overcharged battery cell voltage rises to a certain value, it will be stable for a period of time; when the overcharged battery cell voltage is close to a certain time, it will rise rapidly; when it rises to a certain limit, the cap of the battery cell will be pulled off, and the voltage will drop to 0V. If the battery cell does not fire or explode, it passes the test.

Use a connector with 80mΩ±20mΩinternal resistance to make a fully-charged cylindrical lithium-ion battery cell short circuit on its anode and cathode. Then test the temperature change of battery surface. The highest surface temperature is 140 ℃. Pull off the battery cell cap, if the battery cell does not fire or explode, it passes the test.

Place the fully charged cylindrical lithium ion battery cell in the high temperature cabinet, the temperature is raised to 130℃±2℃ at the rate of (5℃±2℃) /min, and keep the battery cell for 30min. If the battery cell does not fire or explode, it passes the test.

Experiment is conducted to determine whether cylindrical lithium battery cell would explode or cause other destructive damage when burning.

Cylindrical Lithium Ion Battery

Cylindrical battery has the longest development time, the most mature technology and a high degree of standardization. Cylindrical lithium battery has mature winding process, high degree of automation, stable quality and relatively low cost.

Prismatic Lithium Ion Battery

The prismatic lithium ion battery usually refers to the aluminum or steel case prismatic battery. It has high market penetration rate, relatively simple structure, easy production process, light weight, and high relative energy density.

Pouch Cell

A pouch cell is just a liquid lithium ion battery with a polymer case. In the structure, it has aluminum-plastic film package. In the case of safety hazards, the pouch cell may only swell to crack.

|

|

Cylindrical Lithium Ion Battery |

Prismatic Lithium Ion Battery |

Pouch Cell |

| Case Material | Aluminum Alloy, Stainless Steel | Aluminum Alloy, Stainless Steel | Aluminum-Plastic Film |

| Manufacturing Process | Jelly Roll | Rolled And Pressed | Rolled And Stacked |

| Advantages | Mature Technology Good Cell Coherence Low Cost Small Size Flexible Assembly |

Good Heat Dispersion Custom Size High Discharge Platform Good Safety Performance |

Flexible Size And Shape High Energy Density Light Weight Good Safety Performance Small Internal Impedance |

| Disadvantages |

Single Shape Heavy Weight Low Energy Density |

High Cost Poor Stability, High Attenuation |

Complex Process Poor Mechanical Strength Poor Coherence High Cost Leakage Issue |

Lithium ion battery customization is for devices with special needs. The lithium ion battery products we use in daily life do not need to be customized. What need to be customized are those industrial-grade lithium ion batteries. Generally they have demand on lithium ion battery volume, capacity, protective measures, etc.

Volume customization: the volume of cylindrical lithium ion battery can be flexibly customized. The maximum or minimum size can be required within the specified battery specifications.

Voltage and capacity customization: the voltage and capacity of cylindrical lithium ion battery can be customized according to the requirements. Users can customize the lithium ion battery suitable for the equipment according to their own needs.Lithium ion battery can be flexibly customized. The maximum or minimum size can be required within the specified battery specifications.

Safety customization: the lithium ion battery customization manufacturer will increase the battery protection measures according to the environment of the lithium ion battery equipment you use or according to your requirements.