-

Key Takeaways

-

Part 1: Technological Advancements in Cost-Effective Lithium Battery Packs+

- 1.1 Improved Energy Density and Performance Metrics

- 1.2 Innovations in Material Efficiency and Recycling Processes

- 1.3 Enhanced Lifespan and Durability for Industrial Applications

-

Part 2: Economic Factors Driving Cost Efficiency+

- 2.1 Reduced Manufacturing Costs Through Automation

- 2.2 Economies of Scale in Lithium Battery Production

- 2.3 Global Supply Chain Optimization and Material Sourcing

-

Part 3: Impact on Industries and Sustainability Goals+

- 3.1 Supporting Renewable Energy Storage Solutions

- 3.2 Driving Electric Vehicle Adoption and Cost Reductions

- 3.3 Applications in Medical, Robotics, and Infrastructure Sectors

-

FAQ+

- 1. How do lithium battery packs support industrial applications?

- 2. What makes lithium-ion batteries cost-effective in 2025?

- 3. Can lithium batteries help achieve sustainability goals?

Why Lithium Batteries Are More Cost-Effective Than Ever in 2025

May 24, 2025 Pageview:5321

Cost-effective lithium batteries in 2025 are transforming industries with their remarkable efficiency and advanced capabilities. Their affordability has surged due to technological breakthroughs and economic scalability. Key statistics highlight this progress:

The lithium-ion battery market, valued at USD 75.2 billion in 2024, is projected to grow to USD 332.5 billion by 2034.

Utility-scale lithium-ion battery prices have dropped from USD 1400/kWh in 2010 to below USD 150/kWh in 2023.

The automotive sector accounted for 67% of the lithium-ion battery market in 2024, with expectations of surpassing USD 225 billion by 2034.

These advancements make cost-effective lithium battery packs essential for medical solutions, robotics innovations, infrastructure projects, and consumer electronics.

For tailored lithium battery solutions, explore our customized consultation services.

Key Takeaways

Lithium batteries now cost less because of better technology and faster production. They are important for many industries.

New ideas like silicon and lithium-metal anodes store more energy. They improve batteries by up to 50% for medical tools and robots.

Using machines in factories lowers costs and speeds up production. This helps companies get strong and affordable lithium batteries.

Part 1: Technological Advancements in Cost-Effective lithium battery packs

1.1 Improved Energy Density and Performance Metrics

The advancements in lithium battery technology have significantly enhanced energy density and performance metrics, making them more cost-effective and efficient. In 2025, innovations such as silicon anodes and lithium-metal anodes have revolutionized the industry. These developments have increased energy density by up to 50%, enabling batteries to store more energy in a compact form. For instance:

Silicon Anodes: Offer up to 50% improvement in energy density, enhancing safety and rate capability.

Lithium-Metal Anodes: Provide similar energy density improvements but face challenges in cycle life.

Additionally, lithium-sulfur batteries now achieve gravimetric energy densities of up to 450 Wh/kg, surpassing traditional lithium-ion batteries. These advancements are critical for applications requiring high energy density, such as medical devices, robotics, and consumer electronics.

Development Type | Energy Density Improvement | Notes |

|---|---|---|

Silicon Anodes | Up to 50% | Significant enhancements in energy density, rate capability, and safety are highlighted. |

Lithium-Metal Anodes | Up to 50% | Potential improvements but challenges in cycle life and longevity remain. |

Moreover, solid-state batteries are emerging as the next generation battery technology. They offer faster recharge times, better performance in cold weather, and higher durability. These features make them ideal for industrial applications and energy storage systems. By adopting these technologies, you can achieve unparalleled efficiency and reliability in your operations.

1.2 Innovations in Material Efficiency and Recycling Processes

Material efficiency and recycling processes have become pivotal in reducing costs and enhancing sustainability. Modern lithium battery packs incorporate advanced designs that minimize material usage without compromising performance. For example, structural complexity and material diversity are now optimized to improve recycling efficiency. Key metrics include:

Variable Type | Measurement Approach | Example Indicators |

|---|---|---|

Design Characteristics | Measurable indicators reflecting complexity | Structural complexity, material diversity |

Recycling Efficiency | Economic, environmental, and technical metrics | Recycling cost, energy consumption, purity |

Recycling processes have also evolved to recover valuable materials like cobalt, nickel, and lithium. These advancements reduce dependency on raw material sourcing, lowering production costs and environmental impact. For industries like infrastructure and robotics, this translates to more sustainable and cost-effective lithium battery solutions.

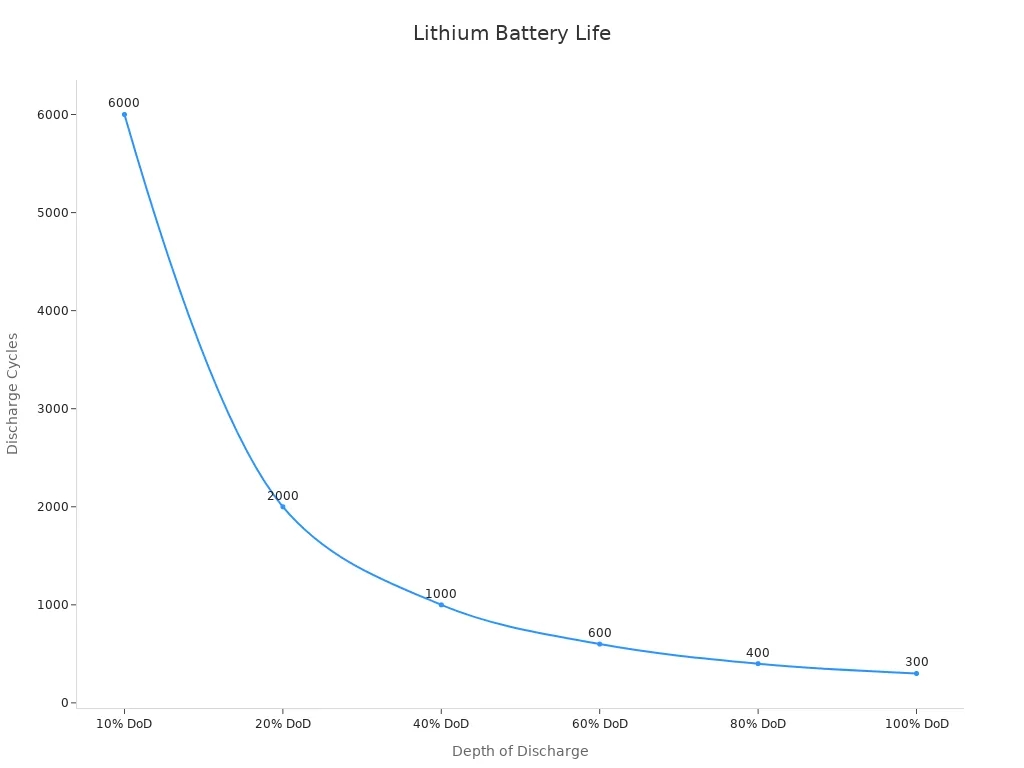

1.3 Enhanced Lifespan and Durability for Industrial Applications

Modern lithium battery packs are engineered for extended lifespans and durability, especially in industrial applications. Depth of discharge (DoD) plays a crucial role in determining battery longevity. For example:

Depth of Discharge | Discharge cycles |

|---|---|

100% DoD | ~300 |

80% DoD | ~400 |

60% DoD | ~600 |

40% DoD | ~1,000 |

20% DoD | ~2,000 |

10% DoD | ~6,000 |

These improvements ensure that lithium battery packs can withstand rigorous usage in industrial environments. NCM lithium batteries, known for their high energy density and cycle life, are particularly suited for such applications. By integrating these batteries into your systems, you can achieve higher efficiency and lower maintenance costs.

For customized lithium battery solutions tailored to your industrial needs, explore our consultation services.

Part 2: Economic Factors Driving Cost Efficiency

2.1 Reduced Manufacturing Costs Through Automation

Automation has revolutionized the production of cost-effective lithium battery packs, significantly reducing expenses while enhancing efficiency. By integrating robotics and IoT technologies into manufacturing processes, companies can achieve measurable cost savings and operational improvements:

Labor costs decrease by up to 30% due to automation and robotics.

Production speed increases by 15%, enabling faster delivery to market.

IoT devices provide real-time monitoring, ensuring consistent quality control.

Predictive maintenance minimizes machinery downtime, reducing operational disruptions.

These advancements not only lower production costs but also improve the commercial viability of lithium battery technology. For industries like robotics and infrastructure, this translates to more reliable and affordable energy solutions. By adopting automated systems, you can streamline operations and maintain a competitive edge in the rapidly evolving battery market.

2.2 Economies of Scale in Lithium Battery Production

The global demand for lithium-ion batteries has surged, driving economies of scale that significantly reduce production costs. As manufacturing scales up, the cost per unit decreases, making lithium battery packs more accessible for various applications, including electric vehicles and industrial systems. Key trends include:

The lithium-ion battery market, valued at $70 billion in 2023, is projected to reach $210 billion by 2030, growing at a CAGR of 15%.

The cost of lithium-ion battery packs has dropped from $1,200/kWh in 2010 to $140/kWh in 2023. Projections suggest prices may fall below $80/kWh by 2030.

Increased production volumes have enhanced the affordability of electric vehicles, accelerating their adoption worldwide.

Year | Battery Pack Cost ($/kWh) | Market Value ($ Billion) |

|---|---|---|

2010 | 1,200 | N/A |

2023 | 140 | 70 |

2030 | <80 | 210 |

These trends highlight the transformative impact of economies of scale on the lithium battery industry. By leveraging this growth, you can access cost-effective lithium battery solutions tailored to your specific needs.

2.3 Global Supply Chain Optimization and Material Sourcing

Optimizing the global supply chain has become essential for reducing costs and ensuring the sustainability of lithium battery production. Companies are adopting innovative strategies to address challenges in material sourcing and geopolitical risks. Key approaches include:

Strengthening relationships with local suppliers to reduce dependency on distant partners.

Prioritizing recycling programs to recover critical materials like nickel, cobalt, and lithium, minimizing reliance on imported raw materials.

Implementing joint development initiatives to accelerate innovation and streamline procurement processes.

Collaboration Strategy | Expected Outcome | Impact on Profits |

|---|---|---|

Supplier Integration | Streamlined procurement processes | Reduce material costs by up to 15% |

Joint Development Initiatives | Faster innovation cycles | Increase product offerings by 20% |

Shared Risk Management | Improved resilience | Decrease downtime by 30% |

These strategies not only enhance efficiency but also mitigate risks associated with global supply chain disruptions. For example, recycling and second-life battery programs could reduce costs by 30% by 2030, further supporting the affordability of lithium battery packs. By focusing on supply chain optimization, you can ensure long-term sustainability and cost efficiency in your operations.

For customized lithium battery solutions tailored to your industry, explore our consultation services.

Part 3: Impact on Industries and Sustainability Goals

3.1 Supporting Renewable Energy Storage Solutions

Lithium battery technology plays a pivotal role in advancing energy storage systems, ensuring the reliability of renewable energy sources. These systems store surplus energy generated by solar and wind power, making it available during peak demand. For example, large-scale projects like Laurel Mountain (32 MW, 8 MWh) and Tohoku, Japan (40 MW, 20 MWh) demonstrate the scalability of lithium-based energy storage.

Location | Power (MW) | Capacity (MWh) | Year |

|---|---|---|---|

Laurel Mountain | 32 | 8 | 2011 |

UK Pilot | 6 | 10 | N/A |

Tohoku, Japan | 40 | 20 | 2013 |

Projected Growth | N/A | 2 GWh/year (2020), 30 GWh/year (2030) | N/A |

Reports like the Lithium-ion Battery Pack Market Report 2025 highlight the growing importance of lithium batteries in renewable energy systems. The market for stationary energy storage is projected to grow at 13% annually from 2025 to 2035, further solidifying their role in achieving sustainability goals. By integrating these energy storage systems, you can enhance efficiency and reduce reliance on fossil fuels.

3.2 Driving Electric Vehicle Adoption and Cost Reductions

The adoption of electric vehicles (EVs) has accelerated due to advancements in lithium battery technology. NCM lithium batteries, known for their high energy density and long cycle life, have made EVs more efficient and affordable. The cost of lithium-ion battery packs dropped by 89% between 2008 and 2022, from $1,355 per kWh to $153 per kWh. This reduction stems from innovations like silicon anodes and increased production volumes.

Evidence Type | Description |

|---|---|

Market Growth | The lithium-ion battery market is projected to reach USD 307.8 billion by 2032, indicating strong growth in battery production. |

Demand Increase | In 2023, over 750 GWh of battery capacity was utilized, a 40% increase from the previous year, reflecting rising EV demand. |

Technological Advancements | Innovations like CATL's long-lasting EV battery and the development of solid-state batteries enhance performance and safety. |

Cost Reduction Efforts | Ongoing efforts to lower production costs and optimize supply chains are making batteries more affordable, supporting EV adoption. |

These advancements make EVs a viable option for businesses aiming to reduce operational costs and carbon footprints. By adopting EVs powered by advanced lithium batteries, you can achieve both economic and environmental benefits.

3.3 Applications in Medical, Robotics, and Infrastructure Sectors

Lithium battery packs have revolutionized industries like medical, robotics, and infrastructure. In the medical field, they power life-saving devices such as portable ventilators and defibrillators, ensuring reliability during critical operations. Robotics applications benefit from the lightweight and high-capacity nature of NCM lithium batteries, enabling longer operational hours and enhanced efficiency. Explore more about robotics solutions from Large Power.

Infrastructure projects, including transportation systems, rely on lithium battery-powered energy storage systems to maintain uninterrupted operations. These batteries provide backup power for critical infrastructure, reducing downtime and enhancing efficiency. By integrating lithium battery packs into your operations, you can achieve superior performance and sustainability.

For tailored lithium battery solutions designed for your industry, visit our customized consultation page.

Lithium batteries in 2025 exemplify cost-effectiveness through technological advancements and economic efficiencies. Industries benefit from stabilized material costs, regional manufacturing expansion, and the adoption of affordable chemistries like LFP. NCM lithium batteries, with their superior energy density and cycle life, are pivotal in achieving global sustainability goals and transforming energy solutions across sectors.

Key benchmarks include:

The lithium primary batteries market is projected to grow from $11.5 billion in 2024 to $12.72 billion in 2025, with a CAGR of 10.6%.

By 2029, the market is expected to reach $17.72 billion, reflecting sustained growth.

For tailored solutions leveraging NCM lithium batteries, explore our customized consultation services.

FAQ

1. How do lithium battery packs support industrial applications?

Lithium battery packs offer high energy density, long cycle life, and durability. These features make them ideal for powering industrial equipment and ensuring operational efficiency.

2. What makes lithium-ion batteries cost-effective in 2025?

Technological advancements, economies of scale, and optimized supply chains have significantly reduced production costs, making lithium-ion batteries more affordable for various industries.

3. Can lithium batteries help achieve sustainability goals?

Yes, lithium batteries enable renewable energy storage, reduce reliance on fossil fuels, and support recycling initiatives, aligning with global sustainability objectives. Explore energy storage solutions from Large Power.

Leave Message

Hottest Categories

-

Hottest Industry News

-

Latest Industry News