-

Key Takeaways

-

Part 1: Understanding Depth of Discharge About Lithium Battery+

- 1.1 What is Depth of Discharge (DoD) in Lithium-Ion Batteries?

- 1.2 How Depth of Discharge Affects Battery Lifespan and Performance

- 1.3 Comparing Shallow vs. Deep Discharge in Lithium Battery Packs

-

Part 2: Best Practices to Limit Depth of Discharge+

- 2.1 Setting Optimal Discharge Limits for Lithium Battery Packs

- 2.2 Benefits of Frequent Partial Charging for Lithium-Ion Batteries

- 2.3 Avoiding Over-Discharge and Its Impact on Battery Health

-

Part 3: The Role of Battery Management Systems in Optimizing Depth of Discharge+

- 3.1 How Battery Management Systems Monitor and Control DoD

- 3.2 Advanced Features of BMS for Industrial and Commercial Applications

- 3.3 Integrating BMS to Enhance Lithium Battery Performance in Key Industries

-

FAQ+

- 1. What are discharge cycles, and why are they important for lithium batteries?

- 2. How does aging affect lithium battery performance?

- 3. Can battery management systems prevent aging in lithium batteries?

How to Manage Depth of Discharge to Enhance Lithium Battery Performance

May 26, 2025 Pageview:3963

Depth of Discharge about lithium battery (DoD) refers to the percentage of energy utilized from a battery compared to its total capacity. This metric is crucial in assessing the performance and durability of lithium-ion batteries, particularly in high-demand applications. In industrial settings, deeper discharges can hasten battery wear, whereas maintaining shallow discharges promotes greater efficiency and extended lifespan. Industries such as medical applications, robotics solutions, security systems, and infrastructure projects depend on accurate DoD management to ensure operational reliability and cost-effectiveness. A thorough understanding of the Depth of Discharge about lithium battery is essential for achieving consistent performance in these critical sectors.

Key Takeaways

Knowing Depth of Discharge (DoD) helps batteries last longer. Keep DoD between 20% and 80% to reduce damage.

Use battery management systems to check and control DoD. These systems stop over-discharge and make batteries more reliable.

Charging batteries partially and often can make them last longer. It lowers stress on parts and keeps them cooler.

Part 1: Understanding Depth of Discharge About Lithium Battery

1.1 What is Depth of Discharge (DoD) in Lithium-Ion Batteries?

Depth of Discharge (DoD) measures the percentage of a battery's capacity that has been used relative to its total capacity. For example, if a lithium-ion battery with a total capacity of 100Ah discharges 40Ah, the DoD is 40%. This metric plays a critical role in determining the operational efficiency and longevity of lithium-ion batteries. You can calculate DoD using the formula:

DoD (%) = (Capacity Used / Total Capacity) × 100%

Understanding DoD is essential for industries relying on lithium-ion batteries, such as medical devices, robotics, and infrastructure systems. These sectors demand consistent and reliable battery performance to ensure uninterrupted operations. Batteries designed for deep-cycle applications, such as LiFePO4 Lithium batteries, are better equipped to handle higher DoD levels without significant degradation. However, higher DoD levels generally accelerate battery wear, making it crucial to manage this parameter effectively.

1.2 How Depth of Discharge Affects Battery Lifespan and Performance

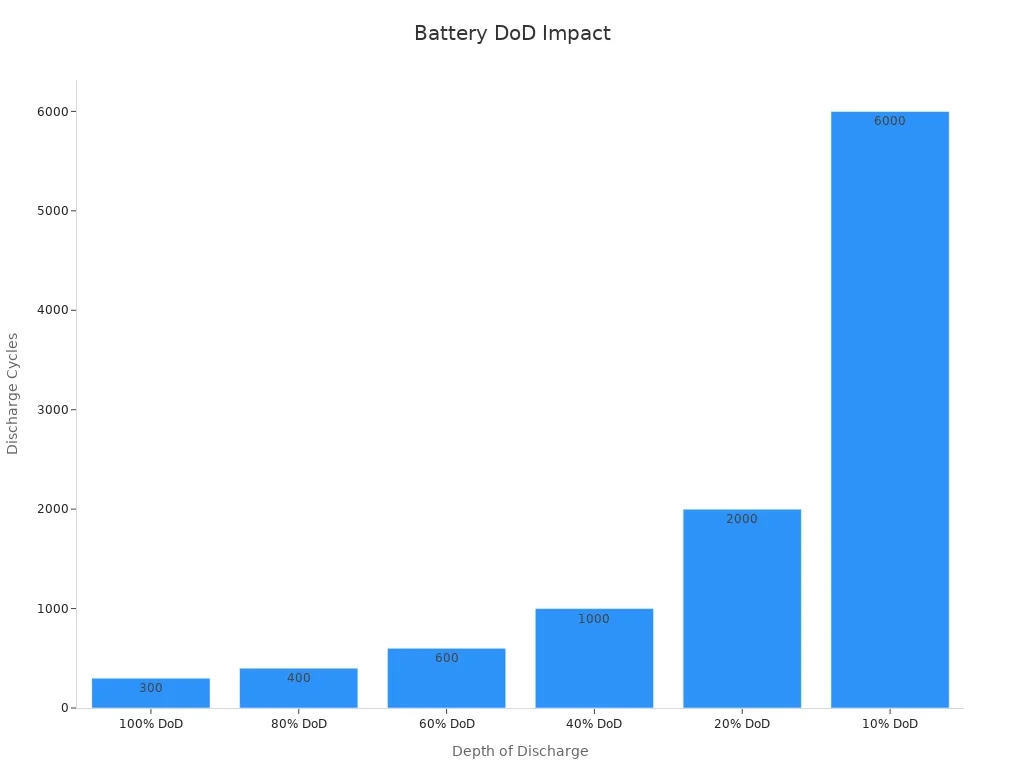

The depth of discharge about lithium battery directly impacts both battery lifespan and performance. Higher DoD levels result in faster degradation of the battery's internal components, including the cathode and electrolyte. This degradation leads to reduced capacity, increased internal resistance, and a shorter overall lifespan. For instance, studies show that discharging a battery to 100% DoD reduces its cycle life to approximately 300 cycles, while limiting DoD to 20% can extend the cycle life to around 2,000 cycles.

Depth of Discharge | Discharge Cycles |

|---|---|

100% DoD | ~300 |

80% DoD | ~400 |

60% DoD | ~600 |

40% DoD | ~1,000 |

20% DoD | ~2,000 |

10% DoD | ~6,000 |

In addition to lifespan, DoD also affects battery performance. Deep discharges generate more heat due to increased internal resistance, which can degrade cell materials and reduce thermal stability. This is particularly critical in applications like industrial automation and energy storage systems, where consistent performance is vital. By limiting depth of discharge, you can optimize battery performance and reduce the risk of premature failure.

1.3 Comparing Shallow vs. Deep Discharge in lithium battery packs

Shallow and deep discharges represent two distinct approaches to battery usage, each with its own advantages and drawbacks. Shallow discharges involve using a smaller percentage of the battery's capacity, while deep discharges utilize a larger portion. The table below highlights the key differences between these two approaches:

Parameter | Shallow Discharge | Deep Discharge |

|---|---|---|

Battery Lifespan | Longer | Shorter |

Heat Generation | Minimal | Higher |

Performance Stability | Consistent | May degrade over time |

Applications | Medical devices, robotics | Energy storage, industrial systems |

Shallow discharges are ideal for applications requiring frequent charging and discharging cycles, such as medical devices and robotics. These applications benefit from the extended lifespan and consistent performance associated with shallow discharges. On the other hand, deep discharges are more suitable for energy storage systems and industrial applications, where maximizing energy output is a priority. However, managing DoD effectively in these scenarios is crucial to prevent excessive wear and maintain operational efficiency.

By understanding the differences between shallow and deep discharges, you can make informed decisions about battery usage and maintenance. This knowledge is particularly valuable for businesses seeking to enhance the reliability and cost-effectiveness of their lithium-ion battery systems.

Part 2: Best Practices to Limit Depth of Discharge

2.1 Setting Optimal Discharge Limits for lithium battery packs

Establishing optimal discharge limits is essential for maintaining the health and longevity of lithium battery packs. You should aim to keep the depth of discharge (DoD) within a range that balances energy usage and battery lifespan. For most lithium-ion batteries, a DoD of 20% to 80% is considered ideal. This range minimizes stress on the battery's internal components, reducing the risk of battery degradation over time.

In industrial applications, such as robotics and infrastructure systems, setting precise discharge limits ensures consistent performance and operational reliability. Battery management systems play a critical role here. These systems monitor the battery's state of charge and automatically regulate discharge levels to prevent overuse. By integrating battery management systems into your operations, you can optimize energy usage while protecting against deep discharge.

Tip: Regularly review your battery's discharge patterns and adjust limits based on the specific requirements of your application. For example, medical devices may require tighter discharge controls compared to energy storage systems.

2.2 Benefits of Frequent Partial Charging for Lithium-Ion Batteries

Frequent partial charging offers several advantages for lithium-ion batteries, particularly in commercial and industrial settings. Unlike full charging cycles, partial charging reduces the strain on the battery's electrodes, slowing down battery degradation. This practice is especially beneficial for applications requiring frequent charge-discharge cycles, such as consumer electronics and robotics.

Key findings from a study on partial charging include:

The analysis focused on real-world usage scenarios, emphasizing partial charging and discharging characteristics.

Data from 300 samples highlighted the effectiveness of partial cycles in maintaining battery capacity.

Charge throughput measurements demonstrated how partial charging extends battery cycle life.

By adopting partial charging, you can enhance the performance and lifespan of your lithium battery packs. This approach also reduces heat generation, which is a common issue during deep discharge cycles. Battery management systems further support this practice by providing real-time data on charge levels, enabling you to implement partial charging strategies effectively.

2.3 Avoiding Over-Discharge and Its Impact on Battery Health

Understanding what happens during deep discharge is crucial for protecting your lithium battery packs. Over-discharge occurs when a battery's voltage drops below its safe threshold, leading to irreversible damage. This condition accelerates battery degradation, reduces capacity, and increases internal resistance. In severe cases, over-discharge can compromise the safety of the battery, posing risks in critical applications like medical devices and security systems.

To protect against deep discharge, you should implement the following measures:

Use battery management systems to monitor voltage levels and prevent over-discharge.

Set alarms or automatic cutoffs to stop discharging when the battery reaches its minimum voltage.

Regularly inspect your battery packs for signs of over-discharge, such as swelling or reduced performance.

The importance of battery management systems cannot be overstated. These systems not only monitor and control discharge levels but also provide insights into the battery's overall health. By leveraging these tools, you can ensure the safety and efficiency of your lithium battery packs across various applications, from industrial automation to energy storage systems.

Note: Avoiding over-discharge is particularly important for LiFePO4 Lithium batteries, which are commonly used in industrial and energy storage applications. Proper management can significantly extend their cycle life, ensuring long-term reliability.

Part 3: The Role of Battery Management Systems in Optimizing Depth of Discharge

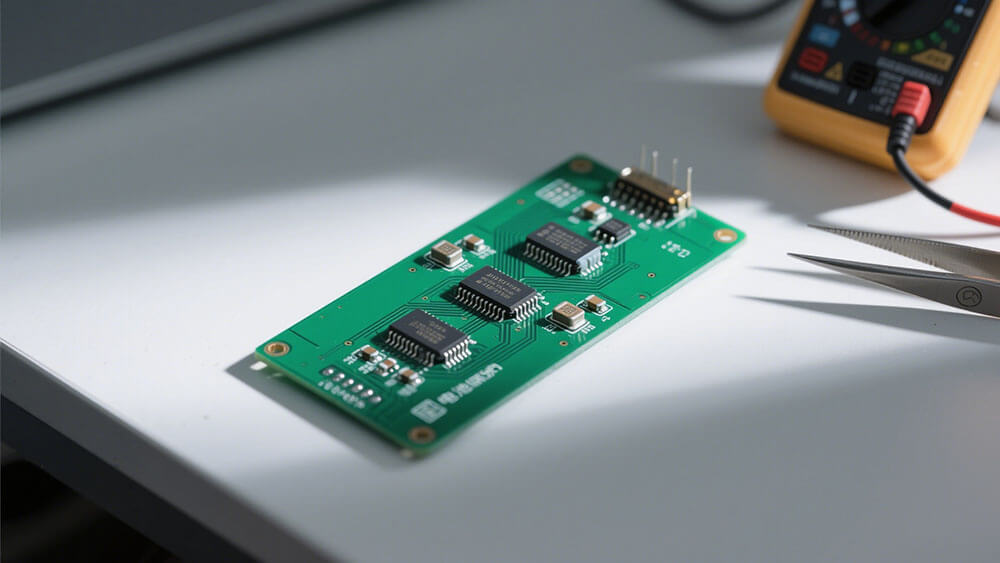

3.1 How Battery Management Systems Monitor and Control DoD

Battery Management Systems (BMS) play a pivotal role in monitoring and controlling Depth of Discharge (DoD) to optimize battery lifetime and performance. These systems track critical metrics such as voltage, current, and temperature across individual cells. By doing so, they ensure safe operation and prevent over-discharge, which can significantly reduce battery life.

Key functionalities of BMS include:

Monitoring State of Charge (SOC) to prevent overcharging or over-discharging.

Regulating voltage to avoid deep discharges that could damage the battery.

Balancing cell performance to mitigate efficiency losses caused by temperature variations.

For industrial applications, such as robotics and infrastructure systems, these features are essential. They enhance operational reliability by maintaining consistent energy output and protecting against irreversible damage. By leveraging BMS, you can improve performance and extend the lifespan of your lithium-ion battery systems.

3.2 Advanced Features of BMS for Industrial and Commercial Applications

Modern BMS incorporate advanced features tailored for industrial and commercial needs. These systems optimize battery performance by maintaining operation within ideal voltage, current, and temperature ranges. For instance, they monitor charge currents to prevent overcharging and track the battery's State of Health (SOH) to predict maintenance needs.

In industrial settings, BMS can achieve high forecasting precision, such as a root mean square error (RMSE) of 0.01173 when predicting the remaining useful life (RUL) of lithium-ion batteries. This level of accuracy ensures timely interventions, reducing downtime and operational costs. Additionally, the integration of AI and machine learning enhances predictive maintenance, further improving battery life and energy efficiency.

3.3 Integrating BMS to Enhance Lithium Battery Performance in Key Industries

Integrating BMS into lithium battery systems is crucial for industries like medical devices, robotics, and energy storage. These systems not only optimize DoD but also enhance safety and performance. For example, in the electric vehicle sector, BMS ensures thermal management and prevents overheating, which is critical for high-energy-density batteries like NMC and LMO Lithium batteries.

In robotics, BMS supports consistent energy delivery, enabling uninterrupted operations in automated systems. Similarly, in infrastructure projects, these systems regulate energy usage, ensuring reliability in critical applications. By adopting BMS, you can achieve better energy efficiency, reduce capacity loss, and optimize battery lifetime. To explore customized solutions for your industry, visit Large Power's consultation page.

Managing depth of discharge is essential for enhancing lithium battery longevity and performance. Studies, such as those by the Electric Power Research Institute, reveal that improper DoD management can reduce battery lifespan by up to 50%. Adopting best practices like setting discharge limits and using partial charging ensures optimal battery health.

Battery management systems further optimize DoD by preventing overdischarge, balancing capacity, and maintaining uniform voltage levels across cells. These features are critical for industrial and commercial applications, where consistent energy output is vital. To explore customized lithium battery solutions tailored to your needs, visit Large Power's consultation page.

FAQ

1. What are discharge cycles, and why are they important for lithium batteries?

Discharge cycles measure how many times a battery completes a full charge-discharge process. They determine battery lifespan and efficiency, especially in industrial applications.

2. How does aging affect lithium battery performance?

Aging reduces battery capacity and increases internal resistance. It impacts discharge cycles, leading to shorter lifespans and decreased reliability in critical systems like medical devices and robotics.

3. Can battery management systems prevent aging in lithium batteries?

Battery management systems optimize discharge cycles and regulate voltage. They slow aging by maintaining ideal operating conditions, ensuring longer battery life and consistent performance.

To explore customized lithium battery solutions tailored to your needs, visit Large Power's consultation page.

- Prev Article: no more

- Next Article: Why Lithium Batteries Are More Cost-Effective Than Ever in 2025

Leave Message

Hottest Categories

-

Hottest Industry News

-

Latest Industry News