How to evaluate the anode performance of lithium battery on seven key indicators

Oct 08, 2019 Pageview:1242

For plate after rolling, its production process has been completed. The subsequent requires the adoption of reasonable production technology for the cathode to exert its own performance.

For lithium ion battery companies, in the actual production process by monitoring the data fluctuation and change, thus discovery, an abnormal rule out as early as possible, so as to achieve the purpose of the mass production smoothly.For plate after rolling, its production process has been completed, the subsequent requires the adoption of reasonable production technology for the cathode to exert its own performance.

1, peel strength:

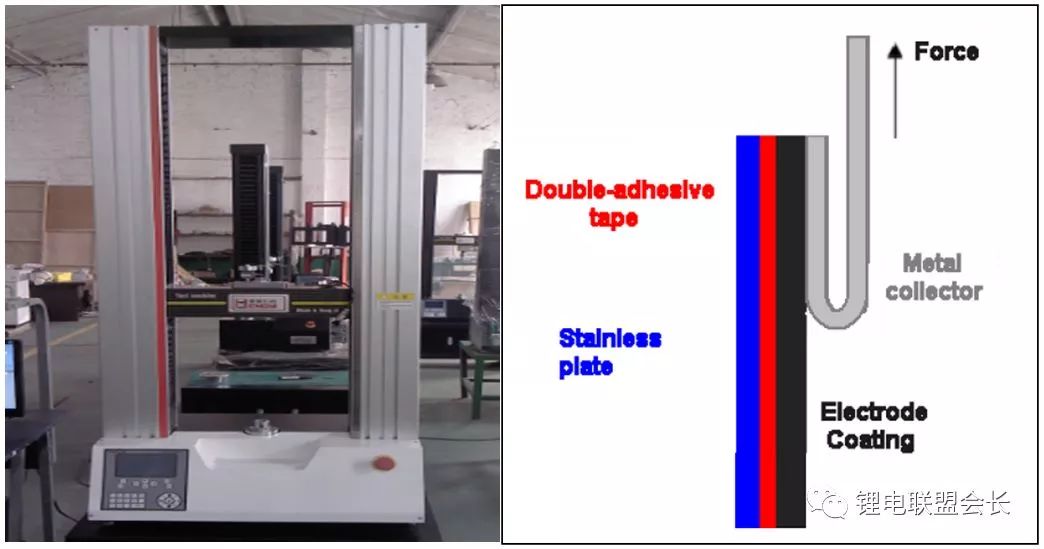

Bonded together material from the contact area of unit width strip is one of the largest force needed, generally with the tensile tester is to test, there are two kinds of test results, a characterization of stripping force, unit as the Newton (N) and kilograms force (KGF), a characterization of peel strength, said of the force per unit length, measured in newtons/m, (N/m) kg force/cm (KGF/cm), industry standard GB2792 and ASTMD3330 now has 25 mm width as standard unit, the test equipment and test principle as shown in the figure below:

Use double-sided adhesive surface under test is fixed on the rigid bracket, the other side on the stainless steel plate, then put the stainless steel plate and the fixed set of fluid in the device's two fixtures, began testing, equipment running at a certain speed and load, when the set is force of fluid is completely stripped down stripping force.It should be pointed out that, on both sides of a sheet of the peel strength is different, need to pay attention to in the process of practical production, the two sides don't vary too big, the peel strength vary too much lead to produce the phenomenon of Yin and Yang in the process of using, impact battery performance.

2, the surface state:

Surface state is actually a very general concept, from a macro sense, the naked eye can see pole piece of can be called the surface state and good state of the cathode surface is smooth, no particles and scratches, feels very smooth;If the naked eye can see, explain the process of coating is a problem, need to adjust the relevant parameters.To introduce here will focus on the microscopic properties of sheet.

Can be seen from the clear picture on the right side of anode materials and conductive agent distribution is not uniform, anode materials have obvious reunion, this distribution can't intuitive on macro, if conductive agent distribution, the battery will impedance increases, in the process of using the local current density is too large, lead to local analysis of lithium and so on, so in practice need to make the cathode materials and conductive agent distribution more uniform, so more conducive to the formation of conductive network, reduce the large current when the problems arising from local polarization is too large.In addition, through SEM also can be seen that particles on the surface of the sheet if there is a broken, reunion, and so on and so forth;And also can analyze the negative pole piece profile, analyze whether cathode materials in a longitudinal uniform distribution, etc., through the comparison of a variety of different materials, can be summed up the relevant experience, the corresponding guidance brings to the subsequent mass production.

3, porosity:

Pole piece of the relationship between porosity to subsequent electrolyte addition amount, at the same time, it is related to the performance.Measurement is generally mercury injection apparatus to test or liquid filling test, subsequent calculated porosity of pole piece.Through the index of different anode materials can the distinction between the physical properties of a first, if the porosity is too big, need to consider to improve the compaction density of material, if the porosity is too small, you need to consider in the subsequent injection liquid ShiYanChang cell incubation time, and so on.

4, the surface resistance:

The surface resistance is also called the surface resistivity.Characterization of the dielectric or electrical insulation materials is an important data.It represents per square area of the dielectric surface of square relative surface leakage current generated by the resistance between the two sides.The unit is the ohm.The size of the surface resistance, besides is decided by the structure and composition of the dielectric with voltage, temperature, surface condition of materials, processing conditions and environmental humidity.The influence of environmental humidity on dielectric surface resistance greatly.The greater the surface resistance, insulation performance is better.

Test data is as small as possible, of course, with different materials, different surface resistivity of conductive agent, we can draw some suitable formula and processing technology, is can be used as a test parameters in the production process of batch test and record the data.

5, fluid absorption performance:

And porosity of the pole, the material of the surface state, is typically used between dry trace of electrolytic liquid droplets on the cathode surface, record completely disappear time, electrolyte through times of multiple measurements, to reach appropriate statistical regularity, which is used to direct production process.

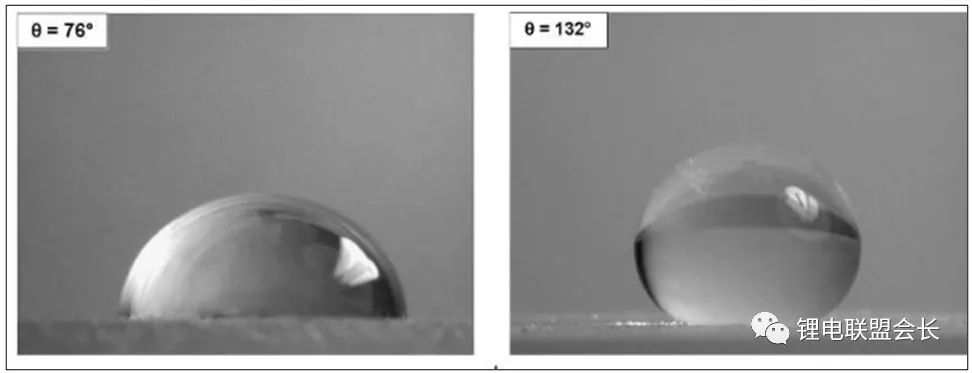

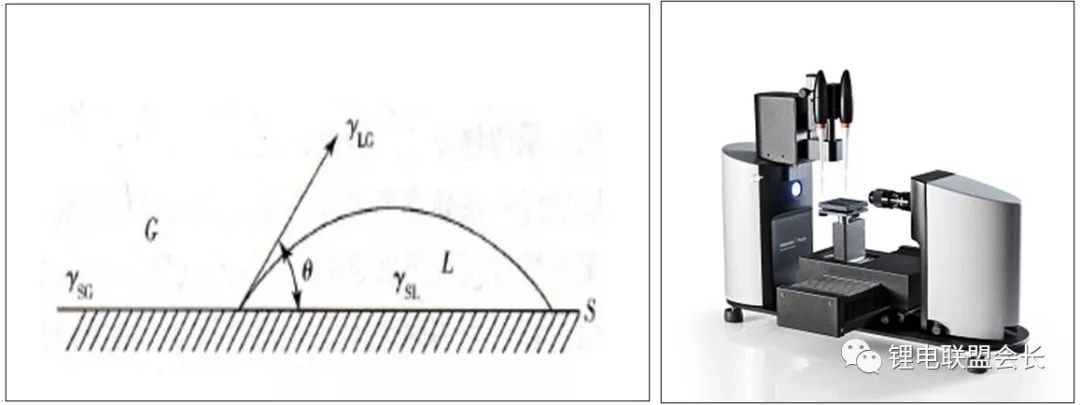

6, contact Angle:

In gas, liquid and solid three phase node location as a tangent to the gas-liquid interface, the tangent in liquid and the Angle between the solid-liquid boundary theta, is a measure of the degree of wetting, wetting process associated with the interfacial tension of system.A drop of liquid on the horizontal solid surface, when balance, from all walks of life with the contact Angle formed by the surface tension between Yang in accordance with the following formula:

Gamma = gamma gamma + x cosine theta

1) when theta equals zero, wetting completely;

2) when theta ﹤ 90 °, partially wetting or wetting;

3) when theta equals 90 °, is the boundary between the wetting or not;

4) when theta st13 90 °, non-wetting;

5) when theta equals 180 °, no wetting.

Anode materials for itself, wetting condition is better, this value may be measured not to come out, but when the porosity is low, it is possible to measure the contact Angle, this parameter can compare different electrolyte and infiltration properties of the cathode materials, has a certain significance.

7, rebound performance:

As now ion battery energy density is higher and higher, the cathode of the coating and the compaction density is also more and more high, so the negative battery pole piece from completed to the finished product to complete this process, the cathode is a certain degree of rebound, so I need to record the different stages of the thickness of the cathode, generally after record after crushing, drying, with the thickness of the electrical dissection, whether changes in order to monitor the thickness of the negative anomaly, through batch sex difference concerns the consistency of production.

Summary: negative pole piece a series of tests, the negative pole piece can be drawn from the basic physical properties, of course, these indicators need to be combined and subsequent performance can be integrated to describe a comprehensive performance on anode materials, to be sure, the anode materials are also suitable for the testing technology.

The page contains the contents of the machine translation.

- Prev Article: What are the advances in solid-state lithium batteries?

- Next Article: A brief description of BYD's power battery business

Leave Message

Hottest Categories

-

Hottest Industry News

-

Latest Industry News