Lithium Battery Production Pollution-Environment and Production

Feb 26, 2020 Pageview:1298

Are lithium batteries environmentally friendly?

Lithium batteries are not environmentally friendly because disposing the battery into the surrounding can cause grave dangers. This is the reason why there are many rules and regulations concerning the disposal of lithium batteries. However, improved versions of the lithium batteries such as lithium-ion and lithium-polymer cells tend to be more environmentally friendly because they have less reactive chemicals as compared to the primary lithium cells.

How are lithium batteries produced?

Lithium is a highly reactive metal, and this prevents it from occurring in its pure or original metal state because if it were to come into contact with moisture in the atmosphere, it could combust spontaneously into flames and spreading to the environment. This also explains why lithium batteries tend to overheat and go through thermal runaway and thus, explode into flames Chile is currently listed as the largest lithium producer worldwide with the leading extraction site located at the famous Atacama Salt Flat.

Lithium is mainly produced from two primary sources and these include igneous rock like spodumene and lithium chloride salts that are found inside brine pools. Lithium extraction from brine is considered a better option because it is a much cheaper procedure as compared to doing it from spodumene rock. For this reason, many spodumene deposits remain unexploited another alternative source of lithium is seawater, but since its concentration levels are deficient, the option of extracting lithium from it is considered uneconomical.

Lithium is a highly reactive compound on the period table and, thus, suitable for the manufacture of glass, pharmaceuticals, high-temperature lubricants, chemicals and the most common of all, lithium batteries. Lithium is found in various compounds and the extraction process involves multiple chemical processes whereby the metal is isolated from its potent mixture and processed into a form or state that can be utilized. Such countries include stable compounds like lithium carbonate.

Extraction from brine

Lithium is primarily produced from liquid brine sites located all over the world below the designated Salt Flats known as salars. Many of these salars are located in South America and China together with other areas rich in brine like oil and geothermal fields. The limitation that comes with extracting lithium from brine deposits is that it is an extremely lengthy process that might even take months or even years to end up with the final usable product.

The process starts with drilling into the surface of the Salt Flats, and the brine is pumped out and transported to the designated evaporation ponds. It is these ponds where the brine is left to evaporate under the sun for all the water to dry up naturally. The brine collected and dumped into the evaporation ponds is in thousands of tonnes and this prevents it from being evaporated manually using a large-scale. The resources needed heating for such methods would be a lot and expensive and would probably end up increasing the production cost which would, ultimately, lead to an inflation of prices. Also, the evaporation process is faced by a couple of obstacles like unexpected rainfalls because the evaporation pits are out in the open field.

Brine has a very high concentration of lithium, potassium, and sodium salts making it easier for these other metals to be extracted as well and put into good use. Many a time, reverse osmosis would be used to concentrate the lithium brine further and thus speed up evaporation. Once the desired concentration of lithium has been achieved in the ponds, it is pumped to a lithium recovery facility for the significant extraction procedure to start. This process is done in the following steps:

Pre-treatment

In this step, filtration and ion-exchange purification processes are used to isolate any impurities from the brine solution. Brine is never a pure solution because it is exposed to many external materials during the mining process and also in the evaporation ponds. As such, the filtration helps prevent any malfunctions that may occur in the extraction process because of the impurities.

Chemical treatments

In this process, chemical solvents and other reagents are added into the filtrated solution to separate the by-products from the desired compounds. The process can be better referred to as precipitation as is commonly known. The chemical solvents and reagents are, however, added in a chronological as well as predetermined order to get the best results. If they were dumped into the solution randomly, the results might turn out to be other than what they were targeting.

Filtration

After being treated with chemicals, the resulting solution is then filtered to isolate the solids that formed from the reaction between the solution and the various chemicals. These solids are known as precipitates and can be used as multiple by-products.

Producing the lithium

In the end, the brine solution is then treated with reagents such as sodium carbonate. Lithium being very reactive, displaces sodium in the compound, therefore, forming lithium carbonate as the resulting compound. This lithium carbonate is after that filtered, dried and then sold. The solution that remains isn’t poured as it can be mixed with reagents to produce other reliable lithium compounds depending on the desired product. Once the extraction process is complete, the solution is pumped back to the salars below the surface.

Extraction from spodumene

Spodumene is also known as igneous or hard rock and caters to a small share of lithium production worldwide. The mineral ore deposits found in spodumene give close to 20 tonnes every year with more than 100 different kinds of minerals containing the same concentration of lithium in them. However, only a few of these lithium deposits from spodumene are exploited because as much as mineral deposits contain higher concentration levels as compared to brine, the fact that they require to be mined from hard rock makes the process very expensive.

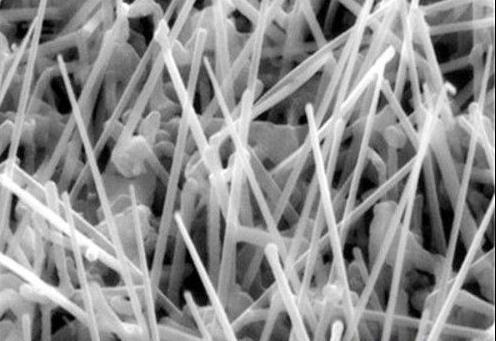

The mineral is crushed and then mixed with particular chemical reagents like sulfuric acid, and the result is heated, filtered and finally concentrated by evaporation. The resulting compound is lithium carbonate which is then collected and transported for further processing in factories to isolate the lithium.

Does lithium battery production lead to pollution?

The production of lithium batteries is a mining process, and this leaves behind large open creaks or holes. This is especially when drilling for brine and in the evaporation ponds. When these holes are left in the open, they might get filled with dirty water and become breeding grounds for various parasites. Even when mining lithium from spodumene, breaking the rocks from the ground leaves an ugly site of the environment.

Conclusion

The demand for lithium keeps increasing, especially with the rise in the manufacture of electric vehicles. However, we should start focussing more on the effects of mining this metal such as pollution in the environment as this could lead to desertification and other environmental hazards.

Leave Message

Hottest Categories

-

Hottest Industry News

-

Latest Industry News