-

Key Takeaways

-

Part 1: How Lithium Batteries Work+

- 1.1 Key Components of Lithium-Ion Batteries

- 1.2 The Role of Charging Speed in Lithium Battery Performance

-

Part 2: The Impact of Fast Charging on Lithium Batteries+

- 2.1 Chemical Processes: Lithium Plating and Degradation

- 2.2 Physical Effects: Heat Generation and Structural Damage

- 2.3 Studies on Fast Charging and Battery Life

-

Part 3: Factors Influencing Battery Degradation+

- 3.1 Temperature and Its Effect on Charging Speed

- 3.2 Charge Rate and State of Charge

- 3.3 Battery Chemistry and Design Considerations

-

Part 4: Practical Strategies to Minimize Fast Charging Damage+

- 4.1 Optimal Charging Practices for Industrial Applications

- 4.2 Leveraging Battery Management Systems (BMS)

- 4.3 Avoiding Extreme Conditions During Charging

-

FAQ+

- 1. How does fast charging affect the lifespan of NMC Lithium batteries?

- 2. Can LiFePO4 Lithium batteries handle fast charging better than LCO Lithium batteries?

- 3. What role does temperature play in fast charging for industrial applications?

Why Fast Charging Damages Lithium Battery Lifespan

May 13, 2025 Pageview:1176

Fast charging can greatly influence the performance and longevity of lithium batteries by inducing chemical changes such as lithium plating and producing excessive heat. For instance, at a 1.67 C charging rate from 0–100% at 0°C, cells retain merely 65% of their nominal capacity after 132 equivalent full cycles. It is crucial to evaluate how charging speed impacts lithium battery lifespan, especially in industrial applications, to enhance performance and minimize costs.

Key Takeaways

Fast charging can damage lithium batteries. It creates heat and lithium buildup, which shortens battery life. Charging slowly keeps batteries healthier.

Keeping the battery charge between 20% and 80% is better. This stops overcharging and helps the battery last longer. Avoid charging to 100% or letting it get too low.

A Battery Management System (BMS) helps watch and control charging. It lowers the chance of damage and makes batteries safer and last longer.

Part 1: How Lithium Batteries Work

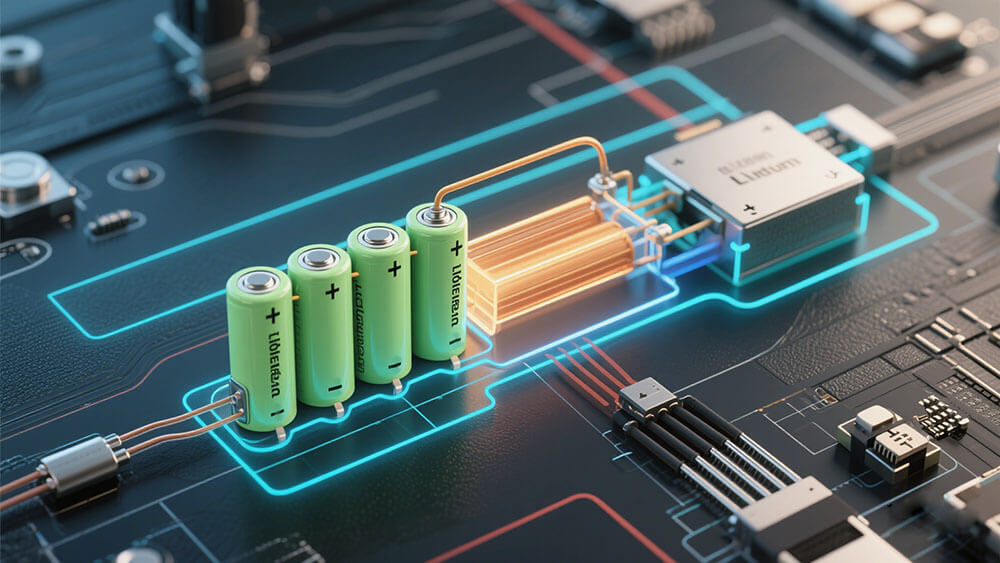

1.1 Key Components of lithium-ion batteries

Lithium-ion batteries consist of several critical components, each playing a unique role in energy storage and transfer. The table below outlines these components and their respective functions:

Component | Typical Composition | Function |

|---|---|---|

Cathode | Lithium, Nickel, Cobalt, Manganese, Aluminum, Iron, Phosphate | Contributes Li-ions through the electrolyte to be stored at the anode side |

Anode | Graphite, Silicon | Stores Li-ions when charged and releases them back to the cathode when discharged |

Separator | Polyethylene | Keeps cathode and anode separated while allowing Li-ions to travel between them |

Current Collector (Cathode) | Aluminum | Collects electrons from the cathode reaction while preventing oxidation |

Current Collector (Anode) | Copper | Collects electrons from the anode reaction while preventing oxidation |

Electrolyte | Solvents and Salts | Provides good conductivity for Li-ions while maintaining thermal stability and a wide operable voltage window |

These components work together to ensure efficient energy transfer and storage. For example, the cathode and anode facilitate the movement of lithium ions during charging and discharging cycles, while the separator prevents short circuits. Manufacturers often use advanced testing methods, such as load cells, to evaluate the mechanical properties and durability of lithium-ion batteries under various conditions. This ensures optimal performance in applications like medical devices, robotics, and instrumentation devices.

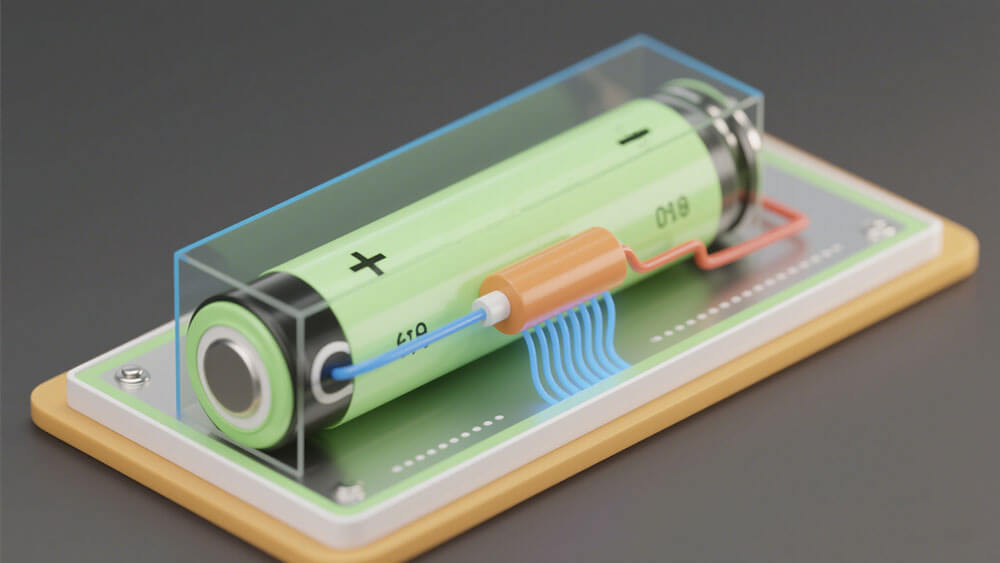

1.2 The Role of Charging Speed in lithium battery Performance

Charging speed significantly impacts the performance and lifespan of lithium-ion batteries. Faster charging rates increase the risk of lithium plating on the anode, which reduces the battery's capacity over time. Additionally, rapid charging generates more heat, potentially leading to thermal runaway and structural damage. These effects are particularly concerning in industrial applications where reliability and longevity are critical.

For instance, in NMC Lithium batteries, which have an energy density of 160–270 Wh/kg and a cycle life of 1,000–2,000 cycles, excessive charging speed can accelerate degradation. Similarly, LiFePO4 Lithium batteries, known for their longer cycle life of 2,000–5,000 cycles, also experience reduced efficiency under high charging rates. By understanding the relationship between charging speed and battery performance, you can implement strategies to optimize charging protocols and extend battery life.

Part 2: The Impact of Fast Charging on Lithium Batteries

2.1 Chemical Processes: Lithium Plating and Degradation

Fast charging accelerates chemical reactions within lithium batteries, often leading to lithium plating. This phenomenon occurs when lithium ions deposit unevenly on the anode surface instead of intercalating into the anode material. Over time, these deposits form dendrites, which can pierce the separator and cause internal short circuits. This not only reduces battery life but also poses safety risks.

Research highlights the intricate chemical changes during lithium plating. For instance, the solid electrolyte interphase (SEI) layer, formed shortly after plating, is predominantly inorganic and can enhance battery performance under controlled conditions. The table below summarizes key findings from a study on lithium plating:

Aspect | Findings |

|---|---|

Chemical Process | Lithium dendrites undergo relaxation, forming a beneficial SEI layer. |

Physical Changes | Morphological changes reduce dendrite coverage, improving performance. |

Capacity Retention | Manipulation strategies improve retention from 80% to 95% over 100 cycles. |

Efficiency Comparison | Protocol time decreases by 80%, with a 23.8% reduction in capacity loss. |

These findings suggest that while lithium plating is a challenge, innovative strategies can mitigate its effects, especially in industrial applications like robotics and medical devices. However, frequent charging at higher rates exacerbates plating, leading to faster degradation.

2.2 Physical Effects: Heat Generation and Structural Damage

Fast charging generates significant heat due to increased current flow. This heat can compromise the structural integrity of lithium batteries, leading to thermal runaway—a condition where excessive heat triggers a self-sustaining reaction. In industrial environments, where reliability is paramount, such failures can disrupt operations and increase costs.

Experimental data illustrates the correlation between heat generation and structural damage. The table below provides insights into these effects:

Evidence Type | Description |

|---|---|

Thermal Runaway | Mechanical abuse causes temperature spikes, leading to structural damage. |

Internal Short Circuits | Damage to internal components generates heat, contributing to thermal runaway. |

Mechanical Abuse Effects | Tests show collisions and punctures directly correlate with structural failure. |

To minimize these risks, you should avoid extreme conditions during charging and implement robust battery management systems (BMS). These systems monitor temperature and current, ensuring safe operation even under demanding conditions.

2.3 Studies on Fast Charging and Battery Life

Numerous studies have explored the relationship between fast charging and battery life. While conventional wisdom suggests that higher charging rates lead to faster degradation, recent research offers a more nuanced perspective. For example:

Analysis of over 160,000 data points reveals no significant difference in range degradation between vehicles that fast charge more than 70% of the time and those that do so less than 30%.

Observed data indicates that fast charging does not always negatively impact battery health, provided that charging protocols are optimized.

Additionally, specific studies have measured the direct effects of fast charging cycles on lithium-ion batteries. The table below highlights key findings:

Study | Findings | Impact on Battery Life |

|---|---|---|

SLAC-Stanford Battery Center | High-current fast charging depletes lithium but increases lifespan by 50%. | Positive effect despite initial lithium loss. |

NMC–Li full cells | Activation with fast-discharging maintains stable cycling for more cycles. | 29% longer cell lifetime compared to non-activated cells. |

These insights emphasize the importance of tailored charging strategies. By leveraging advanced technologies and understanding the nuances of fast charging, you can extend battery life and enhance performance in applications like surveying instruments and handheld devices.

Part 3: Factors Influencing Battery Degradation

3.1 Temperature and Its Effect on Charging Speed

Temperature plays a critical role in the degradation of lithium batteries. High temperatures accelerate chemical reactions within the battery, leading to faster wear and reduced lifespan. For instance, charging at temperatures above 50°C can cause gas generation and damage to the cell structure. Many chargers restrict operation under such conditions to prevent these risks. Conversely, low temperatures can temporarily impair battery performance, making it challenging for lithium ions to move efficiently.

Fast charging exacerbates these issues by generating additional heat. In industrial environments, such as robotics or medical devices, this heat can compromise reliability. To mitigate these effects, you should avoid charging in extreme conditions, such as direct sunlight, and consider using a battery management system to monitor temperature and optimize charging rates.

3.2 Charge Rate and State of Charge

The charge rate directly impacts battery health. Higher charging rates increase the likelihood of lithium plating and heat generation, both of which contribute to degradation. Maintaining a moderate charge rate can significantly extend the battery's lifespan. Additionally, the state of charge (SOC) influences degradation. Charging to 100% or depleting the battery completely accelerates wear. Instead, keeping the SOC within a range of 20% to 80% can reduce stress on the battery.

For example, NMC Lithium batteries, with an energy density of 160–270 Wh/kg, benefit from controlled charging protocols. Similarly, LiFePO4 Lithium batteries, known for their longer cycle life of 2,000–5,000 cycles, perform better when charged at moderate rates. Implementing these practices ensures optimal performance in applications like surveying instruments and handheld devices.

3.3 Battery Chemistry and Design Considerations

Battery chemistry and design significantly influence degradation rates. Variations in manufacturing processes can lead to differences in chemical composition, affecting how batteries respond to fast charging. For instance, LCO Lithium batteries, with an energy density of 180–230 Wh/kg, degrade faster than LiFePO4 Lithium batteries due to their shorter cycle life of 500–1,000 cycles.

Design considerations, such as thermal management systems and advanced separators, also play a role. These features enhance heat dissipation and prevent internal short circuits, reducing the risk of thermal runaway. By selecting the right battery chemistry and incorporating robust design elements, you can improve durability and reliability in industrial applications.

Part 4: Practical Strategies to Minimize Fast Charging Damage

4.1 Optimal Charging Practices for Industrial Applications

Implementing optimal charging practices is essential for reducing the impact of fast charging on lithium battery lifespan. You can achieve this by adopting strategies tailored to the specific requirements of industrial applications, such as robotics, medical devices, and surveying instruments. These practices not only enhance battery performance but also minimize significant capacity loss over time.

Adopt Controlled Charging Rates:

Charging lithium batteries at moderate rates reduces the risk of lithium plating and heat generation. For instance, maintaining a charge rate below 1C can help NMC Lithium batteries, with an energy density of 160–270 Wh/kg, achieve their full cycle life of 1,000–2,000 cycles. Similarly, LiFePO4 Lithium batteries, known for their durability, benefit from controlled charging to maximize their cycle life of 2,000–5,000 cycles.Monitor State of Charge (SOC):

Keeping the SOC within a range of 20% to 80% significantly reduces stress on battery chemistry. This practice prevents overcharging and deep discharging, both of which accelerate degradation. For industrial applications, such as handheld devices and instrumentation devices, maintaining this SOC range ensures consistent performance and reliability.Schedule Charging During Off-Peak Hours:

Charging during cooler periods, such as early mornings or late evenings, helps mitigate heat-related damage. This is particularly beneficial in environments where temperature fluctuations are common.

Tip: Regularly calibrate your charging equipment to ensure it delivers the correct voltage and current. This simple step can prevent unnecessary wear on lithium batteries.

4.2 Leveraging Battery Management Systems (BMS)

Battery Management Systems (BMS) play a crucial role in mitigating the adverse effects of fast charging. By actively monitoring and controlling various parameters, a BMS ensures that lithium batteries operate within safe limits, reducing the likelihood of significant capacity loss.

Feature | Description |

|---|---|

Charging Strategy | The SwRI controller resulted in a charge profile that is 30% faster compared to the manufacturer's recommended strategy. |

Degradation Reduction | The controller significantly reduced battery degradation during fast charging events. |

A real-time BMS actively monitors lithium plating during fast charging and adjusts the charge current to optimize the process. This ensures that the battery charges at a rate aligned with its ability to absorb lithium ions, preventing damage and enhancing longevity. For industrial applications, such as robotics and medical devices, integrating a robust BMS can significantly improve operational efficiency and reduce maintenance costs.

Note: Advanced BMS solutions also provide predictive analytics, enabling you to anticipate potential issues and take preventive measures before they escalate.

4.3 Avoiding Extreme Conditions During Charging

Environmental factors, such as temperature and humidity, have a profound impact on lithium battery performance. Avoiding extreme conditions during charging is critical for extending battery lifespan and maintaining reliability in industrial settings.

High Temperatures: Batteries exposed to temperatures above 45°C degrade much faster than those maintained at 25°C. Heat accelerates chemical reactions within the battery, leading to capacity loss and potential safety hazards.

Cold Temperatures: Charging at low temperatures impairs lithium-ion mobility, increasing stress on the battery and reducing efficiency. For example, LiFePO4 Lithium batteries, with an energy density of 100–180 Wh/kg, perform optimally when charged within their recommended temperature range.

Maintaining a stable charging environment is equally important. You can achieve this by:

Using climate-controlled charging stations to regulate temperature.

Avoiding direct sunlight or freezing conditions during charging.

Implementing state-of-charge management to reduce stress on battery chemistry.

Tip: Regularly inspect your charging infrastructure for signs of wear or damage. Faulty equipment can exacerbate environmental stress and lead to premature battery failure.

By adopting these strategies, you can minimize the risks associated with fast charging technology and ensure the long-term reliability of lithium batteries in industrial applications.

Fast charging significantly affects battery lifespan by increasing heat generation, accelerating lithium plating, and reducing capacity over time. Factors like temperature, charge rate, and battery chemistry amplify these effects. You can mitigate these risks by adopting controlled charging practices, leveraging advanced battery management systems, and avoiding extreme environmental conditions. These strategies ensure reliable performance and longevity, especially in industrial applications.

FAQ

1. How does fast charging affect the lifespan of NMC Lithium batteries?

Fast charging accelerates lithium plating and heat generation, reducing the cycle life of NMC Lithium batteries (1,000–2,000 cycles). Controlled charging rates can mitigate these effects.

2. Can LiFePO4 Lithium batteries handle fast charging better than LCO Lithium batteries?

Yes, LiFePO4 Lithium batteries, with a cycle life of 2,000–5,000 cycles, are more durable under fast charging compared to LCO Lithium batteries, which have a shorter cycle life of 500–1,000 cycles. Learn more about LiFePO4 Lithium batteries.

3. What role does temperature play in fast charging for industrial applications?

High temperatures accelerate degradation, while low temperatures impair performance. Maintaining a stable charging environment ensures reliability in applications like robotics and medical devices.

Tip: For professional guidance on fast chargings, visit Large Power.

- Prev Article: How Low Temperatures Affect Lithium Battery Performance

- Next Article: How Internal Resistance Impacts Lithium Battery Efficiency

Leave Message

Hottest Categories

-

Hottest Industry News

-

Latest Industry News