-

Key Takeaways

-

Part 1: Understanding Internal Resistance About Lithium Battery+

- 1.1 What Is Internal Resistance?

- 1.2 Why Internal Resistance Matters for Battery Performance

-

Part 2: Factors Influencing Internal Resistance in Lithium Batteries+

- 2.1 Battery Chemistry and Material Composition

- 2.2 Temperature Variations and Their Impact

- 2.3 Aging, Degradation, and Cycle Life

-

Part 3: Effects of Internal Resistance on Battery Performance+

- 3.1 Voltage Drops and Power Output Reduction

- 3.2 Heat Generation and Thermal Management Challenges

- 3.3 Impact on Runtime, Capacity, and Lifespan

-

FAQ+

- 1. How does internal resistance affect lithium battery performance in industrial applications?

- 2. What battery chemistry offers the lowest internal resistance for automation devices?

- 3. Can temperature changes influence internal resistance in lithium batteries?

How Internal Resistance Impacts Lithium Battery Efficiency

May 12, 2025 Pageview:1055

Internal resistance about Lithium battery significantly affects performance by influencing heat generation, voltage stability, and energy efficiency. Joule heating, calculated as I²R, demonstrates how higher resistance increases current and generates excessive heat. This directly impacts the runtime and lifespan of batteries used in industrial applications like medical devices, robotics, and instrumentation, where consistent performance is critical.

Key Takeaways

Internal resistance impacts lithium battery efficiency by creating heat and lowering voltage. Less resistance means better performance and longer-lasting batteries.

Picking the right battery type, like LiFePO4, reduces internal resistance. This improves energy use and makes batteries more reliable for important tasks.

Checking internal resistance is important to know battery condition. Regular tests can make batteries last longer and work better in devices like medical tools and robots.

Part 1: Understanding Internal Resistance About lithium battery

1.1 What Is Internal Resistance?

Internal resistance refers to the opposition within a battery that hinders the flow of electric current. It is an intrinsic property influenced by the battery's materials, design, and operating conditions. When current flows through a lithium battery, internal resistance generates heat and causes a voltage drop, which directly impacts its efficiency and performance.

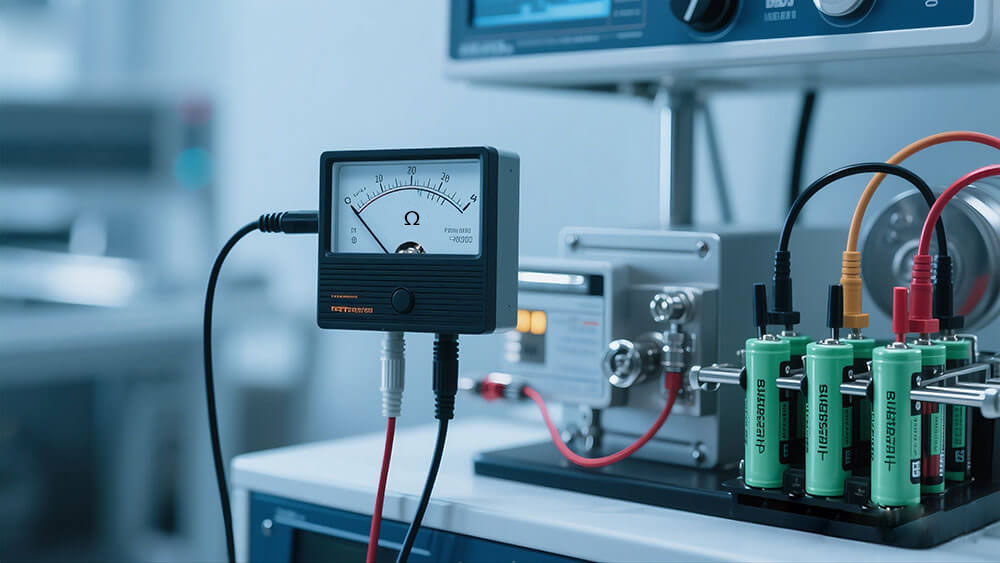

In lithium-ion batteries, internal resistance is typically measured in milliohms (mΩ). It consists of two components: ohmic resistance and polarization resistance. Ohmic resistance arises from the battery's conductive materials, such as electrodes and electrolytes, while polarization resistance results from electrochemical reactions during charge and discharge cycles. Both components vary depending on factors like temperature, state of charge (SOC), and battery aging.

To illustrate, consider the following comparison of internal resistance characteristics across different battery types:

Battery Type | Internal Resistance Characteristics | Performance Implications |

|---|---|---|

Lithium-Ion | Increases with use and aging; improvements with electrolyte additives. | Higher resistance at full charge and end of discharge; responsive in the middle range. |

Lead-Acid | Very low internal resistance; sluggish under sustained high current discharge. | Performs well for short bursts but needs recovery time; affected by sulfation and grid corrosion. |

Nickel-Based | Internal resistance affected by crystalline formation; can be reversed with deep-cycling. | Sluggishness apparent; responsiveness varies with temperature and cycling conditions. |

Understanding internal resistance is crucial for optimizing lithium battery performance, especially in applications requiring high energy output, such as robotics and medical devices. For example, LiMnO2 batteries, known for their low internal resistance, are ideal for digital healthcare applications, while LiFeS2 batteries serve as efficient replacements for alkaline batteries in medical devices.

1.2 Why Internal Resistance Matters for Battery Performance

Internal resistance plays a pivotal role in determining the efficiency, runtime, and lifespan of lithium batteries. A lower internal resistance allows the battery to deliver power more efficiently, reducing energy losses and heat generation. Conversely, higher resistance leads to increased heat, voltage drops, and reduced capacity, which can accelerate battery degradation.

Recent studies highlight the impact of internal resistance on lithium battery performance:

Higher internal resistance requires more effort to maintain voltage, leading to increased heat generation.

This results in reduced efficiency and available capacity, directly impacting runtime.

Aged lithium-ion batteries exhibit significant internal resistance that negatively affects their performance.

For industrial applications like medical devices and robotics, internal resistance is a critical factor. Excell Battery emphasizes selecting battery chemistry based on internal resistance to meet specific load requirements. For instance, LiFePO4 Lithium batteries, with their low internal resistance and high cycle life (2000–5000 cycles), are widely used in automation and instrumentation devices. Their stable platform voltage of 3.2V ensures consistent performance under varying loads.

In energy storage systems, internal resistance determines the battery's ability to handle high current spikes. Research shows that batteries with lower resistance deliver power more efficiently, reducing the likelihood of premature low battery indications. This is particularly important in applications requiring short, high-current bursts, such as surveying instruments and handheld devices.

Note: Monitoring internal resistance is essential for maintaining battery health. Metrics like capacity attenuation rate and DC internal resistance help evaluate battery degradation and estimate life expectancy.

By understanding and managing internal resistance, you can enhance the performance and reliability of lithium batteries in critical applications.

Part 2: Factors Influencing Internal Resistance in lithium batteries

2.1 Battery Chemistry and Material Composition

The chemistry and material composition of a lithium battery significantly affect its internal resistance. Structural design, raw materials, and conductive agents all play a role in determining battery resistance. For example:

Increasing the number of electrode tabs reduces resistance by improving current distribution.

Doping positive electrodes with nickel enhances conductivity and lowers charge transfer impedance.

Using carbon black instead of graphite as a conductive agent improves rate performance and reduces internal resistance.

Coating aluminum foil with conductive materials decreases resistance by up to 65% compared to uncoated foil.

The separator also impacts internal resistance. Its wettability and structure influence ion conduction, which directly affects battery performance. For applications like medical devices and robotics, selecting materials that ensure low internal resistance is critical for maintaining efficiency and reliability.

Study Title | Findings |

|---|---|

Material composition variations directly impact internal resistance and aging characteristics. | |

Baumhöfer et al. (2014) | Initial pulse resistance correlates with cell life, highlighting the role of material variations. |

2.2 Temperature Variations and Their Impact

Temperature fluctuations significantly influence internal resistance. High temperatures accelerate chemical reactions, increasing resistance over time. Conversely, low temperatures slow ion transfer, leading to higher resistance and reduced performance. Below -20℃, charge transfer impedance becomes the dominant factor, severely impacting battery efficiency.

For industrial applications like surveying instruments and handheld devices, maintaining optimal operating temperatures is essential. Batteries with low internal resistance, such as LiFePO4 Lithium batteries, perform reliably across a wide temperature range, making them ideal for such environments.

2.3 Aging, Degradation, and Cycle Life

As lithium batteries age, their internal resistance increases due to electrode degradation and electrolyte decomposition. This rise in resistance reduces capacity, shortens runtime, and accelerates thermal buildup. For instance, NMC Lithium batteries, with a cycle life of 1000–2000 cycles, experience a gradual increase in resistance, impacting their long-term performance.

Monitoring internal resistance helps predict battery health and lifespan. Metrics like capacity attenuation rate and DC resistance provide valuable insights for industrial users. By selecting chemistries with high cycle life, such as LiFePO4 Lithium batteries, you can mitigate the effects of aging and ensure consistent performance in automation and instrumentation devices.

Part 3: Effects of Internal Resistance on Battery Performance

3.1 Voltage Drops and Power Output Reduction

Internal resistance directly impacts the voltage stability of lithium-ion batteries. As resistance increases, voltage drops become more pronounced, especially under high current loads. This phenomenon reduces the power output, affecting the performance of devices relying on the battery. For instance, in robotics or medical devices, voltage sag can lead to operational inefficiencies or even premature shutdowns, compromising critical processes.

Increased internal resistance reduces efficiency and shortens the lifespan of lithium-ion batteries.

Voltage sag under load results in energy loss as heat, diminishing usable capacity.

Devices powered by batteries with high resistance may experience reduced performance or unexpected shutdowns.

For industrial applications, such as surveying instruments or handheld devices, maintaining low internal resistance is essential. It ensures consistent voltage delivery, even during peak power demands. Selecting battery chemistries like LiFePO4 Lithium batteries, known for their stable platform voltage of 3.2V and low internal resistance, can mitigate these issues.

3.2 Heat Generation and Thermal Management Challenges

Heat generation is another critical consequence of internal resistance. When current flows through a battery with high resistance, energy dissipates as heat. This not only reduces efficiency but also poses significant thermal management challenges. Excessive heat can accelerate chemical reactions within the battery, leading to faster degradation and potential safety risks, such as thermal runaway.

In industrial environments, where batteries power automation and instrumentation devices, effective thermal management becomes crucial. High temperatures can compromise battery health, reducing runtime and capacity. For example, NMC Lithium batteries, with an energy density of 160–270Wh/Kg, require robust cooling systems to maintain optimal performance.

Tip: Implementing advanced cooling solutions and monitoring systems can help manage heat generation, ensuring the longevity and safety of lithium-ion batteries in demanding applications.

3.3 Impact on Runtime, Capacity, and Lifespan

The runtime of batteries is directly influenced by internal resistance. Higher resistance reduces the available capacity, shortening the runtime and limiting the battery's ability to sustain high-current loads. Over time, this also affects the overall lifespan of the battery.

For example, LiFePO4 Lithium batteries, with a cycle life of 2000–5000 cycles, maintain low internal resistance throughout their lifespan. This makes them ideal for applications requiring long runtimes and consistent performance, such as medical devices and robotics. Conversely, LCO Lithium batteries, with a shorter cycle life of 500–1000 cycles, experience a more rapid increase in resistance, reducing their long-term efficiency.

Monitoring internal resistance is essential for predicting battery health and optimizing performance. Metrics like capacity attenuation rate and DC resistance provide valuable insights into the aging process. By selecting batteries with high cycle life and low internal resistance, you can enhance runtime, extend lifespan, and ensure reliable operation in critical industrial applications.

Internal resistance plays a pivotal role in determining battery efficiency. It affects voltage stability, heat generation, and overall performance. Factors like material composition, temperature, and aging influence resistance. By monitoring and managing internal resistance, you can extend battery lifespan, enhance energy output, and ensure safety in critical applications like medical devices and robotics.

FAQ

1. How does internal resistance affect lithium battery performance in industrial applications?

Internal resistance reduces efficiency by causing voltage drops and heat generation. This impacts runtime, capacity, and lifespan, especially in robotics and medical devices.

2. What battery chemistry offers the lowest internal resistance for automation devices?

LiFePO4 Lithium batteries provide low internal resistance, stable platform voltage (3.2V), and long cycle life (2000–5000 cycles), making them ideal for instrumentation devices.

3. Can temperature changes influence internal resistance in lithium batteries?

Yes, high temperatures accelerate resistance growth, while low temperatures increase charge transfer impedance. Maintaining optimal conditions ensures reliable performance in surveying instruments and handheld devices from Lagre Power.

- Prev Article: Why Fast Charging Damages Lithium Battery Lifespan

- Next Article: How to Minimize Lithium Battery Self-Discharge During Storage

Leave Message

Hottest Categories

-

Hottest Industry News

-

Latest Industry News